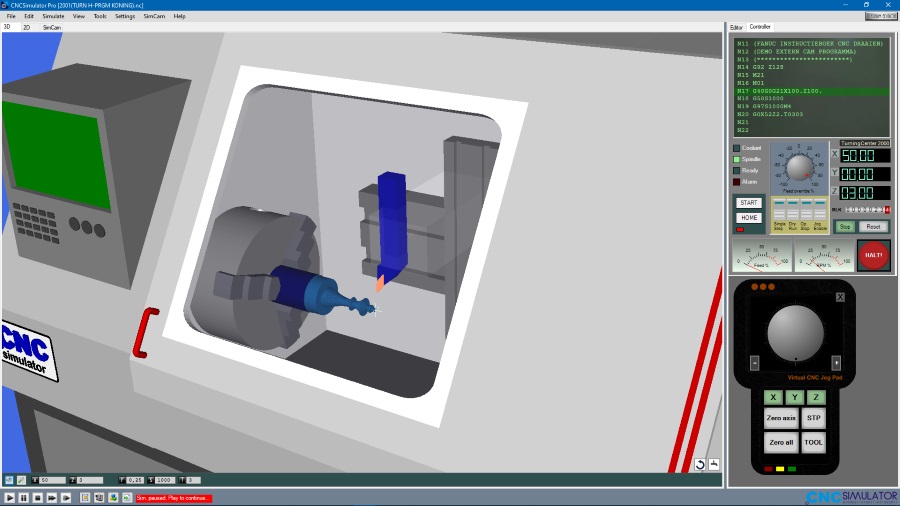

The functionality of the simulator: preparation of texts of control programs of turning operations in the format of a standard GM code, checking control programs for syntax and technological errors, playing on the computer screen (or other computing device) three-dimensional graphic models of the main components of the lathe machine and metal-cutting tools to simulate the process of turning metal, the three-dimensional visualization of the process of forming parts during turning on the compiled control programs, visualization of toolpaths, implementation of interactive user interaction with the simulation model of technological equipment.

BEST CNC SIMULATOR SOFTWARE SOFTWARE

Field of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing». Best I can do to help is to download your solid and create a tool path for you but I need to see.

BEST CNC SIMULATOR SOFTWARE MANUAL

MANUAL GUIDE i installed for easy programming. Lathes system: Servo 2 axes, Spindle 1 axis. Milling system: Servo 3 axes, Spindle 1 axis. Milling and Lathe system switchable on one simulator. Then mastercam uses a postprocessor to translate that data to G-Code and save it as a. CNC Simulator unit for training of operation by actual FANUC Series 0i -F. This tool path holds info like, the cutter dims, feed rate, plunge rate and the path to follow. Material processing is performed on two axes in the horizontal plane. To create G-code I use MasterCam to program a tool path. The basis of the three-dimensional simulation model is a lathe with a classical arrangement of units, equipped with a CNC system, an eight-position turret, a three-jaw chuck, a tailstock, a coolant supply system and other machinery. A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A). Our CNC software is operated via a touchscreen with which you can easily operate your CNC lathe or CNC milling machine.

0 kommentar(er)

0 kommentar(er)